The transformative potential of a 3D printed electronic circuit

The advancements in technology have revolutionized the way we live our lives. From smartphones to smart homes, we are surrounded by devices that make our lives easier and more connected. One of the most exciting technological innovations is 3D printing. This cutting-edge technology has the power to transform various industries, from medicine to manufacturing. In recent years, 3D printing has expanded its capabilities to include the production of electronic circuits. This has opened up a world of possibilities and has the potential to revolutionize the way we think about manufacturing, design, and electronics. In this article, we will explore the transformative potential of a 3D printed electronic circuit.

The Rise of 3D Printing

3D printing, or additive manufacturing, is a process of creating three-dimensional objects by building them layer by layer. It has been around since the 1980s but has gained widespread attention in the last decade due to its increased accessibility and affordability. 3D printing allows for rapid prototyping, customization, and on-demand manufacturing, making it an ideal tool for various industries.

Initially, 3D printing was limited to creating objects using plastic or metal materials. However, with the advancement of technology, new materials such as conductive ink have been developed, making it possible to print electronic circuits. This has opened up a whole new world of possibilities for 3D printing technology.

The Potential of 3D Printed Electronic Circuits

Electronic circuits are an integral part of the technology that we use daily. From smartphones to laptops, every electronic device contains a circuit that allows it to function. Traditionally, circuits are created using a subtractive manufacturing process, which involves removing layers of material to create the desired circuit. This process is time-consuming, costly, and produces a significant amount of waste material.

On the other hand, 3D printing of electronic circuits offers numerous benefits. Firstly, it allows for the creation of complex circuits with multiple layers, which would be challenging to achieve using traditional methods. This results in more compact and efficient devices. Additionally, 3D printed circuits can be customized to fit specific design requirements, making it possible to create unique and innovative products.

One of the most significant advantages of 3D printed electronic circuits is the reduction in production time and costs. The additive manufacturing process is much faster compared to traditional methods, and since it uses only the required amount of material, there is minimal wastage. This makes it a more cost-effective option for manufacturers, leading to more affordable products for consumers.

The Impact on Various Industries

Manufacturing

The manufacturing industry stands to benefit the most from 3D printed electronic circuits. It allows for on-demand production, which eliminates the need for large-scale manufacturing and storage of products. This can greatly reduce costs for manufacturers and also reduce their carbon footprint by minimizing waste.

Medical Industry

The medical industry is another sector that can reap the benefits of 3D printed electronic circuits. With the ability to print electronic circuits on flexible materials, 3D printing can revolutionize medical devices such as sensors and implants. These customized and more flexible devices can provide better accuracy and comfort for patients.

Education

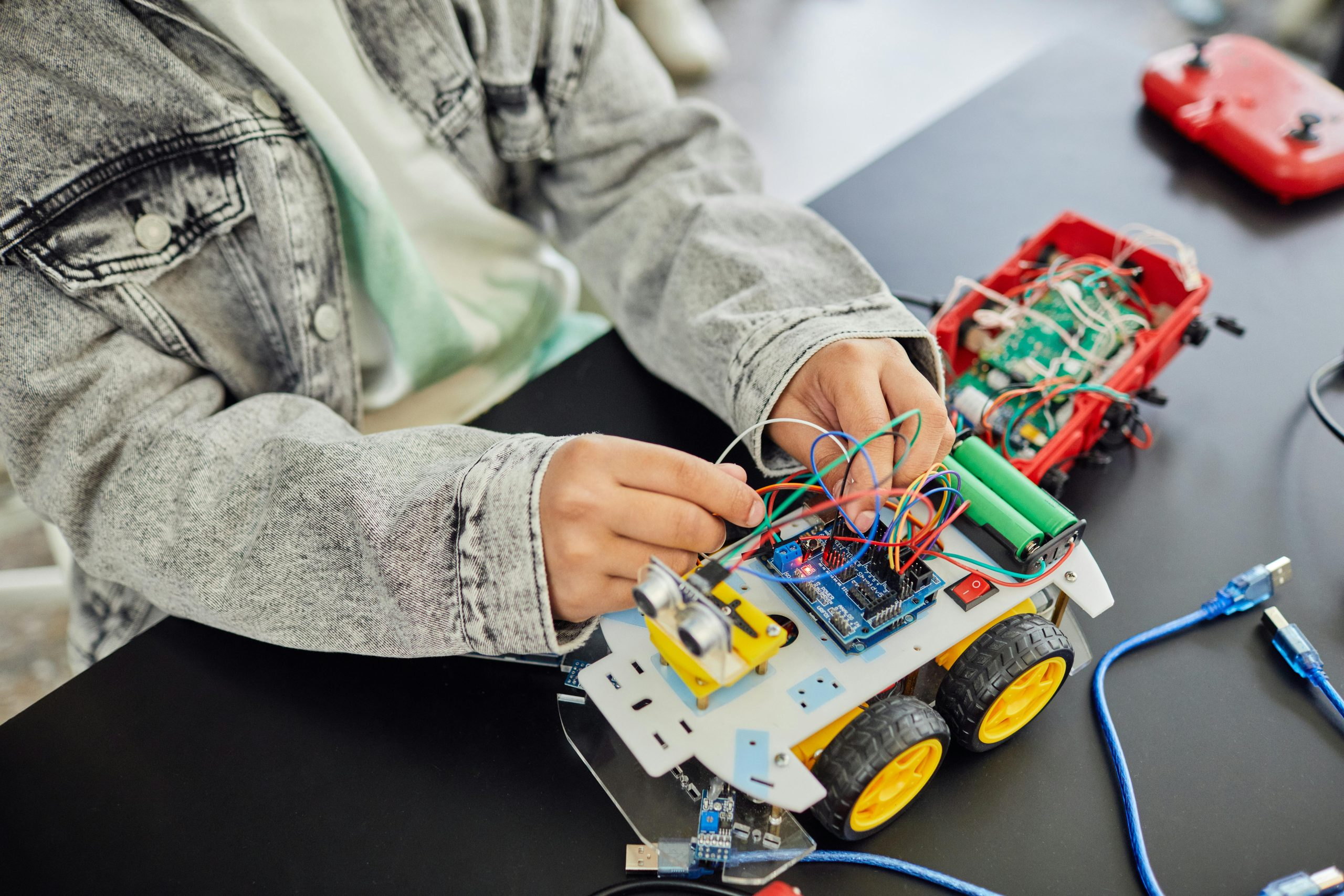

The use of 3D printing technology to create electronic circuits has opened up new opportunities in education. It has become much more accessible for students to learn about circuits and electronics by creating their designs using 3D printers. This hands-on approach helps to foster innovation and creativity in the next generation of engineers and designers.

The Future of 3D Printed Electronic Circuits

The potential of 3D printed electronic circuits is still being explored, and the possibilities are endless. As technology continues to advance, we can expect to see even more complex and efficient circuits being created. This will open up new possibilities for product design, and we may even see a shift towards more personalized and customizable electronic devices.

However, there are still some challenges that need to be addressed before 3D printed electronic circuits become mainstream. These include the development of more conductive and durable materials and improving the speed and accuracy of the printing process.

Conclusion

3D printing technology has the potential to transform various industries, and the addition of electronic circuits to its capabilities takes it to a whole new level. With faster production times, reduced costs, and more customization options, it offers significant advantages over traditional manufacturing methods. As the technology continues to advance, we can expect to see 3D printed electronic circuits making a significant impact on our world and changing the way we think about design and manufacturing.