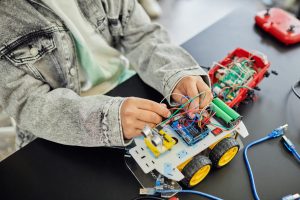

From theory to practice: learning to solder like a professional

Soldering is a fundamental skill in the world of electronics. It involves joining two metal surfaces together using a metal alloy known as solder. The process is essential in creating reliable connections between components on a circuit board, making it an essential skill for professionals in the field. Despite its critical role, soldering can seem intimidating and complicated for those who have never done it before. However, with the right knowledge and techniques, anyone can learn to solder like a professional. In this article, we will take you through the journey of moving from theory to practice and mastering the art of soldering.

The Basics of Soldering

Before diving into the world of professional soldering, it is essential to have a basic understanding of the process. Soldering involves melting the solder and applying it to the joint area between two metal surfaces. The solder acts as an adhesive and creates an electrically conductive connection between the two surfaces. The soldering iron, which is the main tool used in the process, heats up the solder and acts as the heat source.

Types of Solder

There are various types of solders available, each with its unique properties and uses. The most common type is the lead-based solder, which has been widely used for decades. However, due to environmental concerns, lead-free solders are now becoming more popular. It is crucial to choose the right type of solder for your project, as using the wrong one can result in poor connections and even damage to the components.

The Soldering Iron

The soldering iron is the most critical tool for any professional soldering task. It is essential to choose a soldering iron with a temperature control feature to ensure you have the correct temperature for the type of solder you are using. A soldering iron with a small tip is preferred for precision work, while a larger tip is suitable for larger joints.

Learning the Techniques

The key to mastering soldering like a professional is learning the proper techniques, which can be broken down into three main steps – preparing, tinning, and soldering.

Preparation

Proper preparation is crucial for a successful soldering task. First, the surfaces to be joined must be clean and free from any dirt or corrosion. Use a wire brush or sandpaper to clean the surfaces before soldering. Next, make sure the soldering iron is set to the appropriate temperature for the type of solder being used.

Tinning

Tinning is the process of coating the soldering iron tip with a layer of solder. This step ensures good heat transfer and helps prevent oxidation of the tip. To tin the iron, heat it up and then apply a small amount of solder to the tip, making sure it covers the entire surface. Wipe off any excess solder, and your iron is now ready for soldering.

Soldering

Place the soldering iron on the joint area, applying just enough pressure to create a good contact. Next, apply the solder to the joint, not the iron. As the joint heats up, the solder will melt and flow into the joint. Once the joint is coated with solder, remove the iron and let the solder cool down for a few seconds. A shiny, smooth joint is a sign of a successful soldering job.

Practice Makes Perfect

Learning to solder like a professional takes time and practice. The more you do it, the better you will become. Start with simple projects and gradually move on to more complex ones. Remember to always follow safety precautions, such as wearing safety glasses and using a soldering iron stand. With time and practice, you will be able to confidently tackle even the most challenging soldering tasks.

Conclusion

Soldering, like any other skill, requires knowledge, practice, and patience to master. With a good understanding of the basics, the right tools, and the proper techniques, anyone can learn to solder like a professional. Remember to always choose the right type of solder, properly prepare the surfaces, and practice good soldering habits. So next time you need to make a reliable connection on a circuit board, don’t hesitate to pick up that soldering iron and put your new skills to the test.